DIRECT LIQUID COOLING

Servers have become essential in our life, particularly since institutions, companies and consumers use the Cloud daily. The number of data centers keeps increasing. Servers also become more and more powerful and therefore, generate more and more heat. While still widely used in data centers, the potential of traditional air-cooling systems is limited, more so when taking the impact on the environment into account. A few technologies based on liquid emerged, among them is direct liquid cooling (DLC), also called direct to chip liquid cooling.

How Does Direct Liquid Cooling Work?

Contrary to immersion cooling, direct liquid cooling doesn’t involve submerging an entire server in coolant. With this technic, only high power-consuming components are cooled: processors, graphics card...

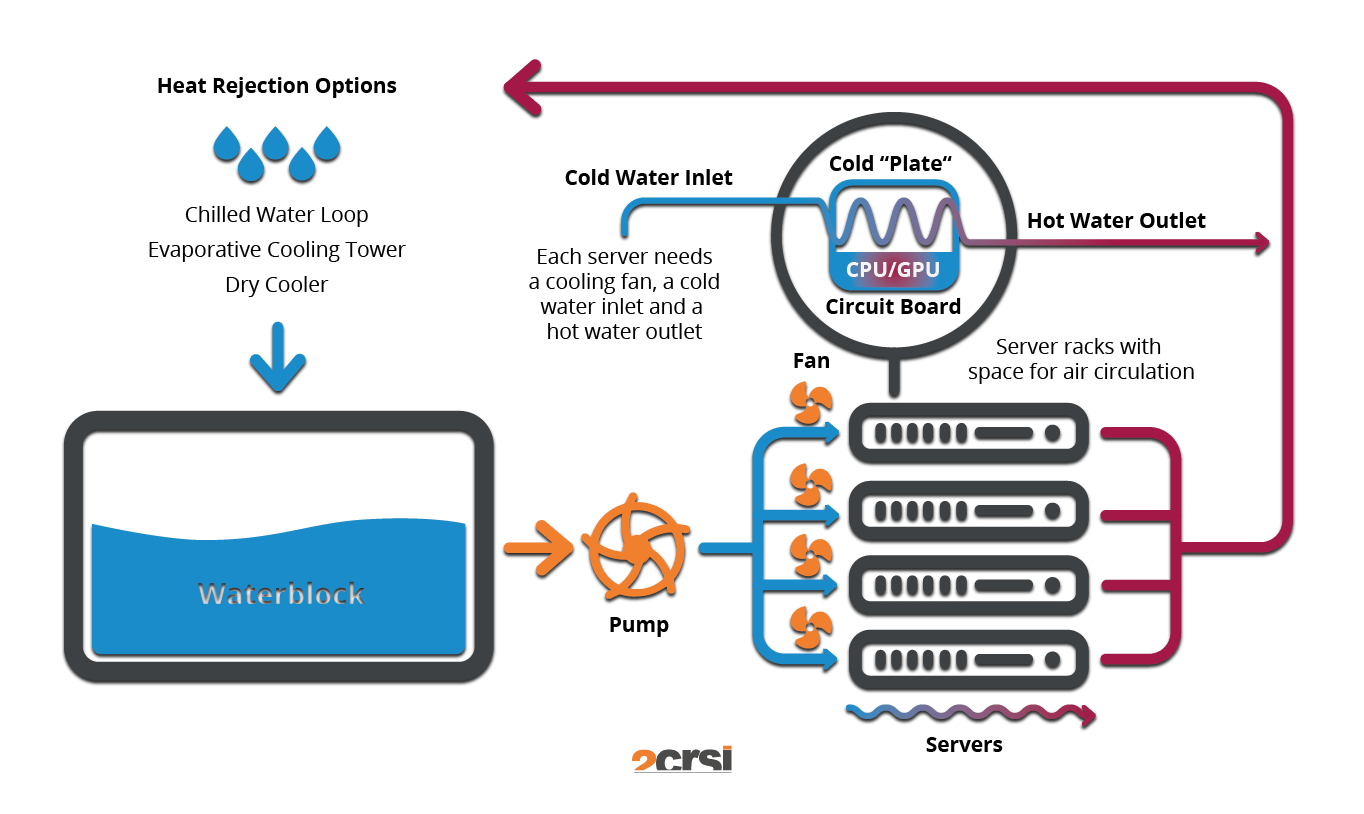

The principle of the DLC is to establish a cooling loop. Cold liquid is sent to cold plates, mounted directly on the hottest components, and absorbs the heat which is sent to a coolant distribution unit (CDU) to a heat exchanger whose function is to dissipate the heat. They are usually located in the rack or shared by rows. When the liquid has been cooled, it is returned to the cold plates, thus closing the cooling loop.

This method of cooling for servers can extract up to 80 kW per rack (60-70% of the heat), improving the data center efficiency and reducing energy costs by up to 45%. The rest of the heat needs to be dissipated with other method, usually from fan wall at the rear of the rack.

Why Using a Direct Liquid Cooling Solution?

If your infrastructure consumes from 20 to 80 kW per rack and you would like to reduce your PUE, your consumed energy, re-use energy and have a better thermic control, direct liquid cooling is a solution you should consider.

Energy efficiency and sustainability

It’s no surprise that the environmental factor plays a big role when choosing a cooling solution. Air cooling has been proved to be the most impactful on the planet due to its numerous fans needing electricity to function. Therefore, energy costs are high, higher than using a liquid cooling solution such as direct on chip cooling.

When comparing air and liquid cooling, the Power Usage Effectiveness (PUE) is essential. It assesses how efficient data centers or tech infrastructures are in using power. To calculate it, divide the total of facility power by IT equipment power. For instance, a datacenter with a 1.25 PUE uses 50 000kWh in total and 40 000kWh is used for IT equipment only. The higher the PUE, the less efficient the data center is, consequently impacting energy costs.

To be efficient, it is estimated that your data center needs to score 1.5 PUE. Data centers using direct liquid cooling system can reach a PUE of less than 1.2 due to the elimination of most of air handling systems. According to the Uptime institute, the average PUE in 2021 was 1.57 compared to 1.59 in 2020.

DLC can also be used to re-use the waste heat by redirecting the heated liquid in a heating system of a building or any other infrastructures.

Flexibility and easy retrofit

Most data centers still possess an air-cooling system. Switching to a new cooling solution such as direct liquid cooling can seem complicated. However, the existing data center infrastructure can be reused with minor reconstruction and modification. This process is called retrofitting. When a facility goes through this process, cost-effective options are provided to increase efficiency and/or capacity without changing the building infrastructure.

Reducing noise pollution

It is well-known that fans make a lot of noise. In a data center using air cooling, the noise is high and constant, rending the working conditions of technicians difficult and, in the long run, dangerous for their hearing.

Direct liquid cooling needs less fans, greatly reducing the noise pollution and creating a better work environment for the maintenance technicians who can stay longer inside the facility and concentrate fully.

Easy maintenance

Compared to air cooling, direct to chip cooling is simpler to maintenance. For instance, the cooling lops can be separated from other equipment without affecting it, meaning the rack doesn’t need to be shut down to be worked on.

Direct Liquid Cooling: Single-phase and Two-phase

When using liquid cooling in general, the process can be categorized in two categories operating at the chip level.

Single-phase cooling

In a single-phase cooling, the hydrocarbon-based dielectric liquid (similar to mineral oil) or the water doesn’t change state while gathering the fatal heat. A cold plate is placed on the chip, so components are not in direct contact with the fluid. Fans are still needed to provide airflow to remove the heat through the server.

They work with us!

Two-phase cooling

Two-phase cooling uses evaporation units. The low-pressure dielectric fluid changes state, from liquid to steam, when removing the fatal heat off the components. The liquid used is fluorocarbon-based, which boils at 50°C. It’s more expansive and needs to be handled with care.

These two cooling methods can remove about 70-75% of the fatal heat generated by the components in the rack, leaving 25-30% that needs to be removed by air-cooling systems such as fans.

They work with us!

2CRSi's DLC ready servers

The OCtoPus range

2CRSi believes since day one in liquid cooling solution to cool its servers. The OCtoPus is a range of servers based on OCP principles, containing servers in the 3 mains type of cooling systems, direct liquid cooling being one of them.

OCtoPus 2EE

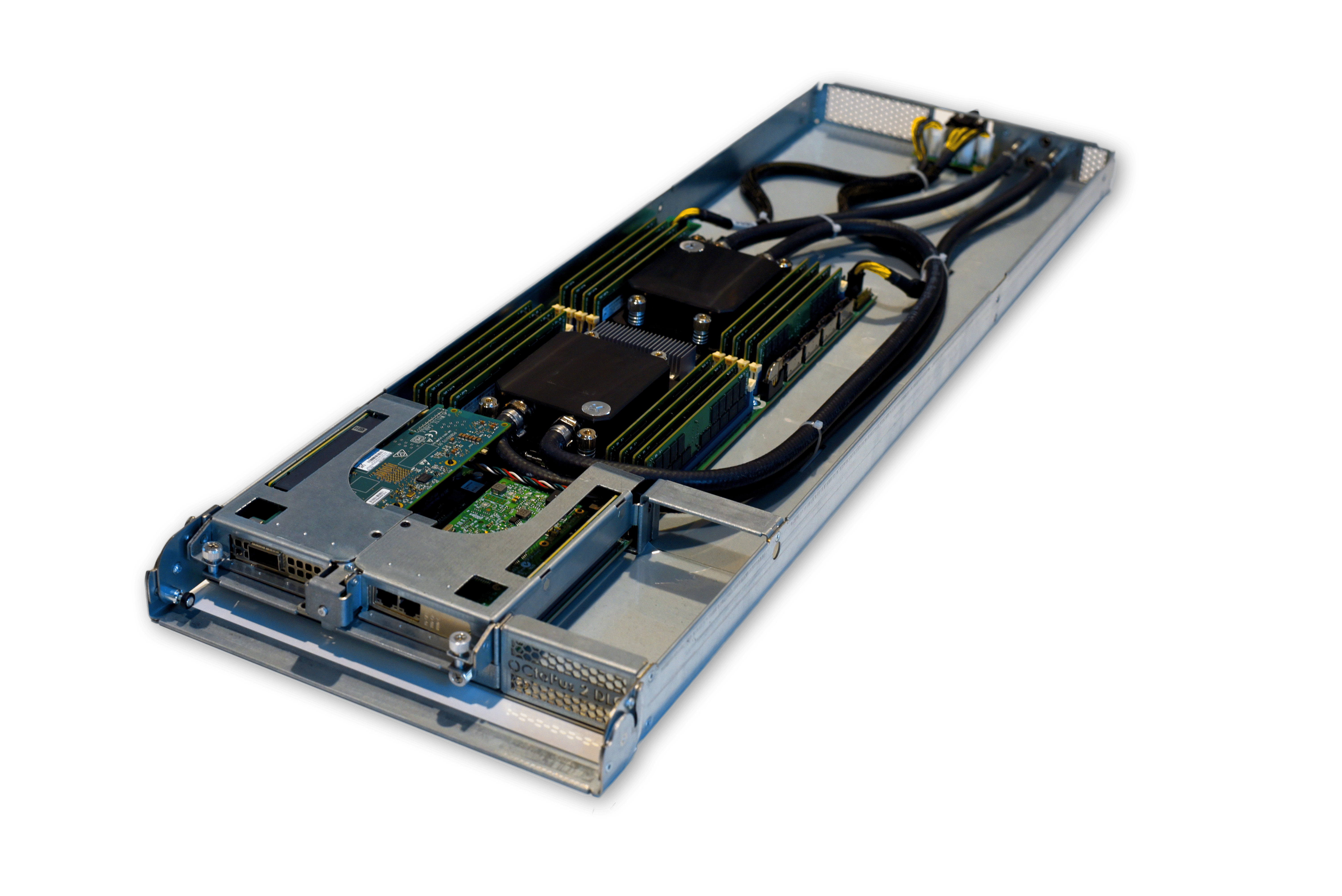

The OCtoPus 2EE in 1OU 21" is composed of two blade nodes, two sockets for 7002 or 7003 series AMD EPYC™ processors and 8 DIMMs slots per CPU. Oour DLC servers are equipped with leak-proof blind mate connectors that need to be attach to the manifolds. This design was thought to make technicians work simpler during maintenance: no more pipes to disconnect, only pull the server back to remove it from the rack!

OCtoPus 1.4

The OCtoPus 1.4 is designed for GPU and FPGA support. It's the only server embedding up to 4 accelerators in the front of the machine (Front IO). In addition, it has been thought specially to power high-demanding environments: financial computing, machine learning, data search, analytics...

We have 3 declinations of the OCtoPus 1.4: with one AMD processor, two AMD processors or two Intel processors.

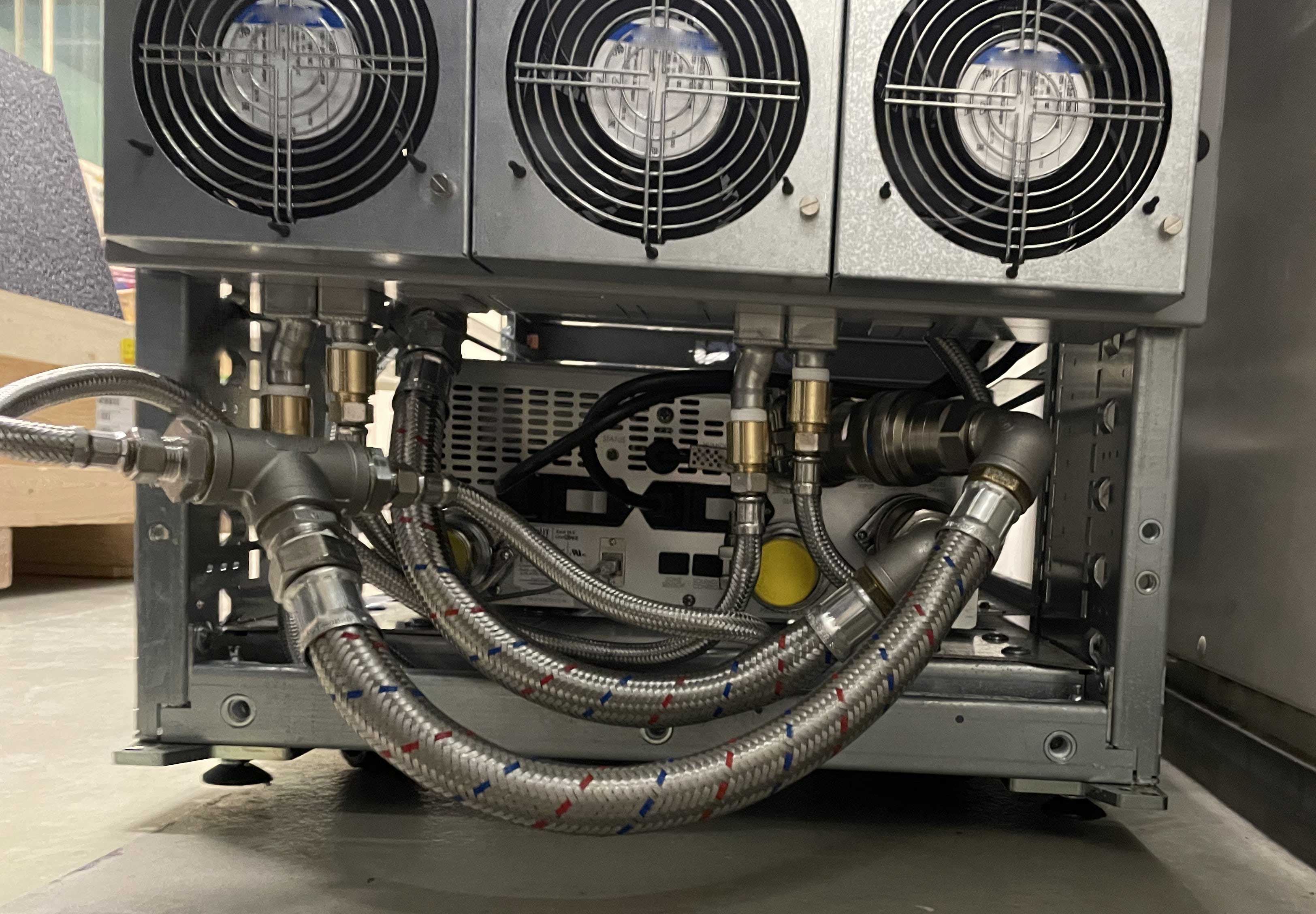

OctoRack

To complete our OCtoPus range, we also designed racks. The OctoRack 42SL is a 42OU rack based on OCP principles. It's equipped with an enhanced air-cooled fan wall solution and DLC infrastructure. Learn more about the OctoRack!

The Kraken

The Kraken stands as the exclusive workstation boasting dual motherboards, making it an unparalleled product that pushes the boundaries of possibilities. With this powerhouse, you have the flexibility to combine two operating systems, enabling you to tackle various tasks based on your preferences. Powered by cutting-edge components, the Kraken excels in executing any task effortlessly, even when handling multiple projects simultaneously, courtesy of its dual nodes.

This exceptional workstation is a collaborative venture between 2CRSi and Ansys, the global leader in engineering simulation. Learn more about the Kraken!